We integrate sustainability into every aspect of our operations. From eco-friendly packaging and zero-pollution manufacturing to durable motorcycle parts and starting batteries, MTX is committed to reducing environmental impact while supporting a cleaner future.

ECO-Friendly at MTX

At MTX, we don’t just manufacture motorcycle parts and starting batteries — we create sustainable solutions. Our ECO-Friendly commitment runs through every step of our business, from using biodegradable packaging and zero-pollution production to developing durable products that extend lifecycle and reduce waste. We believe that caring for the environment, practicing ethical governance, and supporting our communities are essential to building a better future.

Sustainability is at the heart of MTX

We integrate sustainability into every aspect of our operations. From eco-friendly packaging and zero-pollution manufacturing to durable motorcycle parts and starting batteries, MTX is committed to reducing environmental impact while supporting a cleaner future.

Sustainability is at the heart of MTX

Transparency builds trust at MTX

We are committed to openness in the way we operate. By sharing our progress clearly, we give partners and customers confidence in our long-term vision.:

Measuring today, shaping tomorrow

hrough quarterly reports and real-time updates, MTX not only tracks current performance but also sets clear goals for the future, ensuring accountability at every step.

Sustainability guides MTX’s growth

Sustainability is central to our long-term strategy. By adopting eco-friendly packaging, zero-pollution production, and durable product design, MTX ensures responsible growth while contributing to a cleaner future for the powersports industry.

Collaboration and innovation shape our impact

We believe progress comes through working together. By fostering strong partnerships and driving innovation in motorcycle parts and starting batteries, MTX is dedicated to creating positive change and delivering lasting value to our customers and communities.

COMMITTED TO A GREENER FUTURE

At MTX, we are proud to play our part in protecting the environment. We believe that every effort, no matter how small, contributes to a cleaner and more sustainable world. Guided by this vision, we continuously explore better ways of designing, producing, and delivering our products.

Today, MTX has achieved a fully eco-friendly product line, ensuring that every item we bring to market reflects our dedication to environmental responsibility.

MTX ACHIEVEMENTS

Environmental

- Established a fully owned factory with zero-loss and zero-pollution production standards

- Converted all product packaging to biodegradable, eco-friendly materials

- Integrated lifecycle design to extend product durability and reduce waste

Social

- Sponsored world champion rider Courtney Duncan, showcasing MTX’s commitment to motorsports

- Strengthened employee training and workplace safety programs

- Enhanced community engagement through regional partnerships

Governance

- mplemented strict quality control and transparency across the supply chain

- Adopted real-time monitoring systems to track performance and set improvement goals

- Built a governance framework aligned with international sustainability standards

WHAT OUR BATTERY FACTORY PROVIDE

At MTX, we are committed to minimizing the environmental impact of our production processes. Our factory utilizes globally advanced emission treatment equipment to effectively filter and control harmful gases produced during manufacturing. These state-of-the-art systems ensure that all emissions meet international environmental standards, with real-time monitoring for continuous compliance.

Harmful Gas Emission Control

At MTX, we are committed to minimizing the environmental impact of our production processes. Our factory utilizes globally advanced emission treatment equipment to effectively filter and control harmful gases produced during manufacturing. These state-of-the-art systems ensure that all emissions meet international environmental standards, with real-time monitoring for continuous compliance.

Water Recycling and Conservation

At MTX, we have implemented a large-scale water recycling system across our entire factory. This advanced system efficiently recycles and reuses water, while also treating wastewater to ensure it meets environmental standards. Our approach reduces water consumption, minimizes waste discharge, and supports our commitment to sustainability.

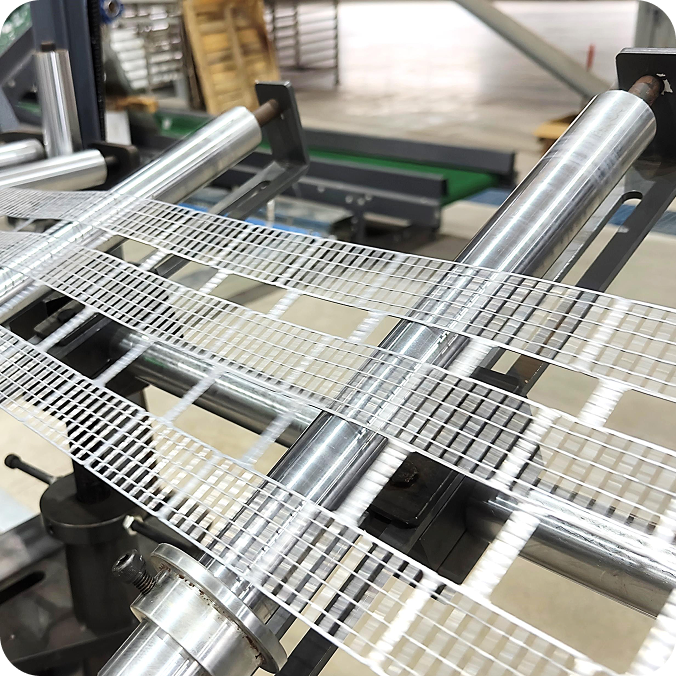

Lead Plate Stamping for Zero Loss

At MTX, we use a stamping process for our lead plates that allows for the collection and reuse of lead materials during production. This method ensures that all lead is efficiently recovered and reintroduced into the production cycle, achieving true zero loss and minimizing waste.

Automated Production Process

t MTX, our entire production process is fully automated, with preset system logic ensuring precise execution at every stage. This automation eliminates the possibility of human error, while also preventing the loss of materials, such as acid, ensuring maximum efficiency and minimal waste.